A Continuous Load is Load Where the Maximum Current is Expected to Continue for

In Article " Overcurrent Protection – Part One ", which was an Introduction to Overcurrent Protection, I provide the basic information needed for best understanding of the Overcurrent protection.

Today, I will answer the following questions:

- How to size the overcurrent protection devices (OCPDs)?

- How to select the proper overcurrent protection for certain applications?

1- Sizing of overcurrent protection devices (OCPDs)

Definitions:

Continuous loads: loads where the maximum current is expected to continue for 3 hours or more.

Non-continuous loads: other loads than Continuous Loads.

Rule#1: Sizing of overcurrent protection devices (OCPDs)

As per NEC section 210.20(A) and 21.5.3(A), Where a branch circuit or Feeders supplies continuous loads or any combination of continuous and non-continuous loads, the rating of the overcurrent device shall not be less than the non-continuous load plus 125 percent of the continuous load.

Rating of the overcurrent device = non-continuous load + 125 % of the continuous load

Example#1:

Solution:

A store has a lighting branch circuit which includes 4 lighting luminaires, each luminaire draw 4 Amps and is working for more than 3 hours. What the Rating of the overcurrent device required for this branch circuit?

Since the lighting luiminaires are working more than 3 hours, it will be continuous load. By applying rule#1:

Example#2:

Rating of the overcurrent device = non-continuous load + 125 % of the continuous load = 0 + 125 % x (4x4A) = 20 A

Solution:

What is the Size of overcurrent protection on a branch circuit with 10 Amps of continuous load and 15 amps of non-continuous load?

By applying rule#1: Rating of the overcurrent device = non-continuous load + 125 % of the continuous load = 15 + 125 % x 10 = 27.5 A 27.5 A is not a standard overcurrent device size. The next larger size is 30 amps. The Rating of the overcurrent device should be rated 30 amps. .

Exception to Rule#1

Where the assembly, including the overcurrent devices protecting the branch circuit(s) or Feeders, is listed for operation at 100 percent of its rating, the ampere rating of the overcurrent device shall be permitted to be not less than the sum of the continuous load plus the noncontinuous load.

in this case:

Rating of the overcurrent device = non-continuous load + continuous load

Rule#2: Relation between overcurrent device Rating and Circuit/Feeder Amapacity

As per NEC Section 210.19(A)(1), The rating of the overcurrent device cannot exceed the final ampacity of the circuit/feeder conductors after all the derating or correction factors have been applied, such as for temperature or number of conductors.

2- How to select the proper overcurrent protection for certain applications?

Imporatant!!!

Article 240 of the National Electric code provides the general requirements for

overcurrent protection as follows:

- Parts I through VII are for protective devices not more than 600 volts nominal.

- Part VIII is for supervised industrial applications operating at less than 600 volts

- Part IX is for overcurrent protection greater than 600 volts, nominal.

Article 240 explains how to protect:

- Conductors,

- Flexible Cords and Flexible Cables,

- Fixture Wires.

First: Protection of conductors

Rule#3: General Rule for overcurrent Protection of Conductors

Select an overcurrent protection device (OCPD) that protects conductors (other than flexible cords, flexible cables, and fixture wires) based on their ampacities (after application of ampacity correction and adjustment per NEC section 310.15).

Exception to Rule#3

several exceptions to Rule#3 exists as follows:

- Power loss hazard.

- OCPDs rated 800A or less.

- OCPDs rated over 800A.

- Small Conductors.

- Tap Conductors.

- Transformer secondary conductors

- Specific applications.

1- Power loss hazard:

2- OCPDs rated 800A or less:

Overcurrent Protection is not allowed for power loss hazard circuits

As per 240.4(A), if circuit interruption will create a hazard such as in fire pump circuit or a material-handling magnet circuit, you must provide short circuit protection, but you don't have to provide conductor overload protection.

Overcurrent Protection Device Rating = Next higher standard rating above the conductor ampacity This is permitted if all of the following conditions are met:

- The conductors do not supply multi-outlet receptacle branch circuits.

- The ampacity of a conductor after ampacity adjustment and/or correction doesn't correspond to the standard rating of a fuse or circuit breaker.

- The protection device rating doesn't exceed 800A.

3- OCPDs rated over 800A

4- Small Conductors Unless specifically permitted in 240.4(E) or (G), the OCPD rating for Small Conductors shall not exceed the following:

The rating of the overcurrent device ≤ the ampacity of the conductors it protects (after application of ampacity correction and adjustment per NEC section 310.15).

| Size of Conductor | OCPD rating | Conditions |

| 18 AWG Copper | 7 A | (1) Continuous loads do not exceed 5.6 amperes. (2) Overcurrent protection is provided by one of the following: a. Branch-circuit-rated circuit breakers/ fuses listed and marked for use with 18 AWG copper wire b. Class CC, Class J, or Class T fuses |

| 16 AWG Copper | 10 A | (1) Continuous loads do not exceed 8 amperes. (2) Overcurrent protection is provided by one of the following: a. Branch-circuit-rated circuit breakers/fuses listed and marked for use with 16 AWG copper wire b. Class CC, Class J, or Class T fuses |

| 14 AWG Copper | 15 A | |

| 12 AWG Aluminum and Copper-Clad Aluminum | 15 A | |

| 12 AWG Copper | 20 A | |

| 10 AWG Aluminum and Copper-Clad Aluminum | 25 A | |

| 10 AWG Copper | 30 A |

5- Tap Conductors:

Definition:

Tap Conductors: is a conductor, other than a service conductor, that has overcurrent protection ahead of its point of supply that exceeds the value permitted for similar conductors that are protected as described elsewhere in 240.4.

Tap conductors are those branch circuit and feeder conductors subject to the special overcurrent protection requirements specified in 240.21.

Tap conductors shall be permitted to be protected against overcurrent in accordance with the following:

| Tap conductors | NEC Code Section |

| For Household Ranges and Cooking Appliances and Other Loads | 210.19(A)(3) and (A)(4) |

| For Fixture Wire | 240.5(B)(2) |

| Location in Circuit | 240.21 |

| Reduction in Ampacity Size of Busway | 368.17(C) |

| Feeder or Branch Circuits (busway taps) | 368.17(B) |

| Single Motor Taps | 430.53(D) |

6- Transformer secondary conductors: The secondary circuit conductors from a transformer must be protected by overcurrent devices in the primary circuit conductors of the transformer only in the following two special cases:

- A transformer with a 2-wire primary and a 2-wire secondary provided the transformer primary is protected in accordance with 450.3.

Example#3:

Except for those two special cases, transformer secondary conductors must be protected by the use of overcurrent devices, because the primary overcurrent devices do not provide such protection.

Solution:

A single-phase transformer with a 2-wire secondary is provided with primary overcurrent protection rated at 50 amperes. The transformer is rated 480/240 volts. Conductors supplied by the secondary have an ampacity of 100 amperes. Is the 50-ampere overcurrent protection allowed to protect the conductors that are connected to the secondary?

The secondary-to-primary voltage ratio in this example is: 240 / 480 = 0.5 Multiply the secondary conductor ampacity by this ratio: 100 amperes x 0.5 = 50 amperes As per NEC 240.4(F), the maximum rating of the overcurrent device allowed on the primary of the transformer that will also provide overcurrent protection for the secondary conductors is 50 amperes. These secondary conductors are not tap conductors, are not limited in length, and do not require overcurrent protection where they receive their supply, which is at the transformer secondary terminals.

7- Specific applications:

Overcurrent protection for the specific conductors shall be permitted to be provided as referenced in Table 240.4(G) (in below image) .

Second: Protection of Flexible Cords and Flexible Cables Flexible cord and flexible cable shall be protected by an overcurrent device in accordance with their ampacity as specified in Table 400.5(A)(1) and Table 400.5(A)(2)

Flexible cord shall be protected, where supplied by a branch circuit, in accordance with one of the three following methods:

2- Extension Cord Sets:

1- Supply Cord of Listed Appliance or Luminaire:

Where flexible cord or tinsel cord is approved for and used with a specific listed appliance or luminaire, it shall be considered to be protected when applied within the appliance or luminaire listing requirements.

3- Field Assembled Extension Cord Sets:

Flexible cord used in listed extension cord sets shall be considered to be protected when applied within the extension cord listing requirements.

Flexible cord used in extension cords made with separately listed and installed components shall be permitted to be supplied by a branch circuit in accordance with the following:

| Branch Circuit Ampacity | Extension Flexible Cord Size |

| 20-ampere circuits | 16 AWG and larger |

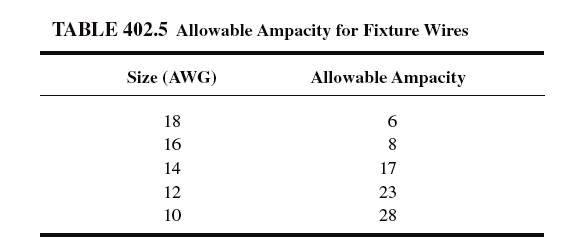

Third: Protection of Fixture Wires Fixture wire shall be protected against overcurrent in accordance with its ampacity as specified in Table 402.5 (in below image) Supplementary overcurrent protection, as covered in 240.10, shall be permitted to be an acceptable means for providing this protection.

Overcurrent Protective Device, Supplementary:

It is a device intended to provide limited overcurrent protection for specific applications and utilization equipment such as luminaires and appliances. This limited protection is in addition to the protection provided in the required branch circuit by the branch-circuit overcurrent protective device.

The definition of supplementary overcurrent protection device makes two important distinctions between overcurrent protective devices:

- First, the use of a supplementary device is specifically limited to a few applications.

- Second, where it is used, the supplementary device must be in addition to and be protected by the more robust branch-circuit overcurrent protective device.

Fixture wire shall be permitted to be tapped to the branch-circuit conductor of a branch circuit in accordance with the following:

| Branch Circuit Ampacity | Fixture Wire Size |

| 20-ampere circuits | 18 AWG, up to 15 m (50 ft) of run length |

| 20-ampere circuits | 16 AWG, up to 30 m (100 ft) of run length |

| 20-ampere circuits | 14 AWG and larger |

| 30-ampere circuits | 14 AWG and larger |

| 40-ampere circuits | 12 AWG and larger |

| 50-ampere circuits | 12 AWG and larger |

Summary for Conductor Sizing And Protection

The following steps should help in understand the basic rules of conductor sizing and protection:

Step#1: Size the overcurrent device in accordance with Rule#1 or exception to Rule#1.

Rule#1: Rating of the overcurrent device = non-continuous load + 125 % of the continuous load

Exception to Rule#1: Rating of the overcurrent device = non-continuous load + the continuous load

Step#2: Select the conductor to comply with 210.19(A), 215.2, and 230.42(A).

Sections 210.19(A), 215.2 and 230.42(A) require the conductor to be sized no less than 100% of the noncontinuous load, plus 125% of the continuous load.

In addition, 110.14(C) requires consideration of the temperature rating of the equipment terminals when sizing conductors. Circuit conductors must be sized according to the 60°C column of Table 310.15(B)(16) for equipment rated 100 amperes and less, unless marked otherwise, and equipment rated over 100 amperes must be sized to the 75°C column of Table 310.15(B)(16) [110.14(C)]. The purpose of this rule is to insure that the heat generated on equipment terminals can be properly dissipated without damaging the conductors. For all practical purposes, most electrical equipment is design to accept conductors sized to the 75°C column of Table 310.15(B)(16).

Step#3: The selected conductor must be protected against overcurrent in accordance with Rule#3.

This requires the branch circuit, feeder, and service conductors be protected against overcurrent in accordance with their ampacities as specified in Table 310.15(B)(16).

Example#4:

Solution:

What size feeder overcurrent protection device and conductor (THHN) is required for a 184A continuous load on a panelboard (75°C terminals)?

Step#1: Size the overcurrent device in accordance with Rule#1. Rule#1: Rating of the overcurrent device = non-continuous load + 125 % of the continuous load Rating of the overcurrent device = 0 + 125% x 185 A = 230 A According to 240.6(A) we must select a minimum 250A overcurrent device. Step#2: Select the conductor to comply with 215.2, which requires the feeder conductor to be sized no less than 125% of the continuous load. We must select the conductor according to the 75°C temperature rating of the panelboards terminals [110.14(C)] you will ind that 4/0 THHN has a rating of 230A at 75°C will meet this requirement. Step#3: Verify the conductors selected in Step#2 is properly protected against overcurrent in accordance with Rule#3. The 4/0 AWG conductor from Step 2 is rated 230A at 75°C, it is permitted to be protected by a 250A protection device in accordance with the "the next size up rule" of 240.4(B). In the next Article, I will answer the following questions:

- How to select the proper overcurrent protection devices (OCPDs) for certain application?

- Where to locate the overcurrent protection devices (OCPDs)?

Please, keep following.

brinkmansaithereadd.blogspot.com

Source: http://www.electrical-knowhow.com/2013/03/overcurrent-protection-part-two.html

0 Response to "A Continuous Load is Load Where the Maximum Current is Expected to Continue for"

Post a Comment